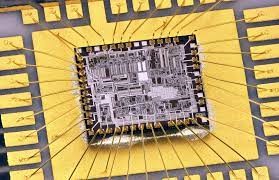

A wire bonder is a machine that allows connecting microcircuits via a sub-millimetre wire made of gold or alloy to the case/carrier pins.

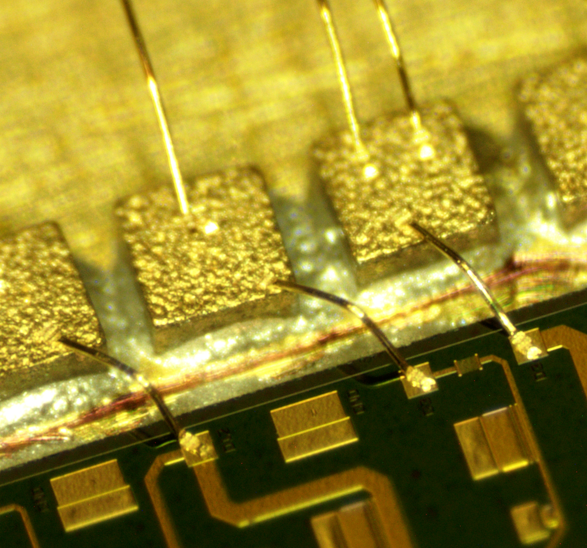

Uses ultrasonic vibration and pressure for the mechanical soldering of the wires to the pads.

It allows connecting thin wire (75, 35, 25 or 18 um) to the pads of a device or a microcircuit without using welding material. The connection is performed only by pressure and ultrasonic vibration. The machine consists of an arm mechanically connected to a generator of ultrasonic vibrations with a tool at the tip. Inside di arm and the tool flows the wire needed, which is welded.

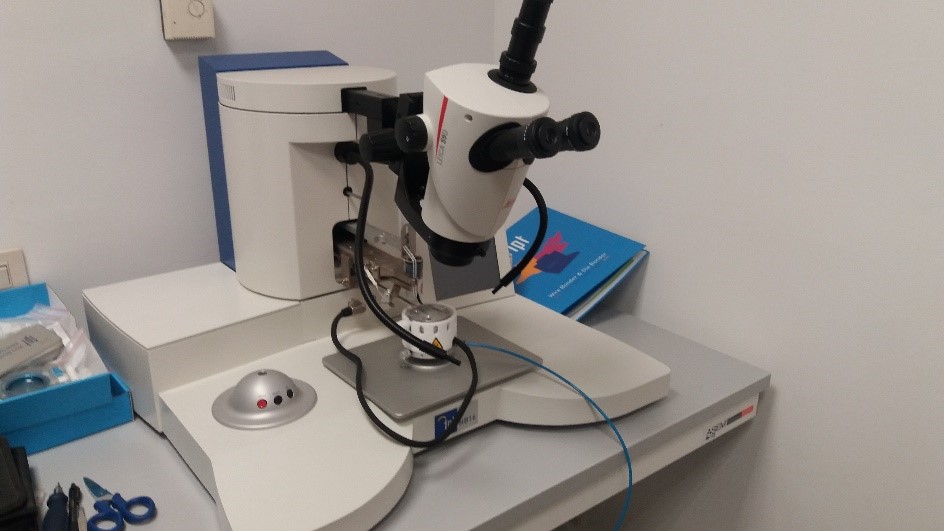

Prof. Ernesto LimitiLaboratory : NANOMICROFAB

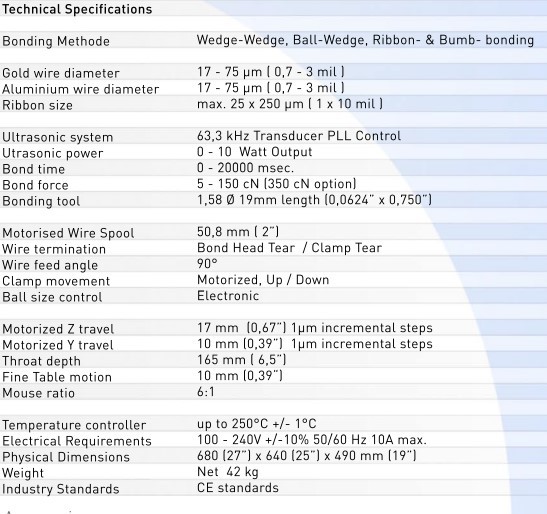

The TPT HB16 is a semi-automatic wire bonder with motorized Z- & Y- Axes, ideal for laboratories and pilot production lines.

One bond head for bonding in Ball/Wedge or Wedge/Wedge bonding mode. Only tool change necessary. Easy operation with TFT Touch Screen and direct access and simple adjustment of all bond parameters.

AVAILABLE TECHNIQUES

Wedge Bonding

Ball Bonding Automatic X and Z axes

SAMPLE

- MMICs (GaAs, GaN, Si,

HMICs (Al2O3, soft/woven substrates,

USE FOR

- Semiconductor/ Microelectronics

- Microcircuits

- Soldering

Case Studies

DC/RF decoupling networks assembly of a GaN HPA MMIC